Marine Components Replacement Blade Cutter Stainless Steel 316 OEM Sharp Edge CNC Machined Cutter

Stainless Steel 316 Marine Blade Cutter | OEM CNC Machined Sharp Edge for Boat Propellers, Pumps & Marine Equipment - High Corrosion Resistance & Precision Replacement Parts

CNC MACHINING SERVICES

9/26/20255 min read

Unveiling the Excellence of Custom Stainless Steel 316 Replacement Blades

In the realm of industrial components, the demand for high-quality replacement blades is ever-present. Whether it's for marine equipment, manufacturing machinery, or other heavy-duty applications, the performance and durability of a blade can significantly impact the overall efficiency of the system. This is where our custom stainless steel 316 replacement blades come into play, offering a blend of precision, reliability, and longevity that sets them apart from the competition.

The Superiority of Stainless Steel 316 Material

At the heart of our replacement blades lies the exceptional material - stainless steel 316. This alloy is renowned for its outstanding corrosion resistance, making it an ideal choice for applications in harsh environments. Whether it's exposure to saltwater in marine settings or corrosive chemicals in industrial processes, stainless steel 316 can withstand the test of time, ensuring that the blade maintains its integrity and performance over the long haul.

Not only does stainless steel 316 offer excellent corrosion resistance, but it also provides remarkable strength and durability. This means that our replacement blades can handle heavy loads and high-stress situations without compromising on their cutting ability. Whether you're cutting through tough materials or performing repetitive cutting tasks, our blades will deliver consistent and reliable results.

Precision Engineering for Optimal Performance

Our custom replacement blades are not just made from high-quality materials; they are also crafted with precision engineering techniques. Each blade undergoes a meticulous manufacturing process that includes plate cutting, CNC machining, and deburring to ensure a perfect fit and optimal performance.

The CNC machining process allows us to achieve tight tolerances, ensuring that every blade meets the exact specifications required by our customers. This level of precision is crucial for applications where even the slightest deviation can result in poor performance or equipment failure. Additionally, the deburring process removes any sharp edges or burrs, ensuring a smooth and safe cutting surface.

One of the key features of our replacement blades is their polished and sandblasted surface. This dual treatment not only enhances the aesthetic appeal of the blade but also serves a practical purpose. The polishing process removes any scratches or dents, creating a smooth surface that reduces friction and improves cutting efficiency. The sandblasting process, on the other hand, adds texture to the surface, increasing its grip and preventing the blade from slipping during use.

Customization to Meet Your Specific Needs

We understand that every application is unique, which is why we offer a wide range of customization options for our replacement blades. Whether you need a specific size, shape, or surface treatment, we can work with you to create a blade that meets your exact requirements.

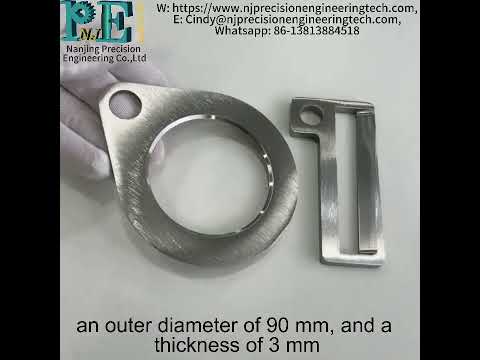

For example, our custom replacement blade with an inner diameter of 60 mm, an outer diameter of 90 mm, and a thickness of 3 mm is designed to fit perfectly into specific machinery or equipment. Similarly, our long replacement blade, measuring 90 mm in total length, 45 mm in width, and 6 mm in thickness, with a 12.1 mm diameter hole and an 80 mm blade length, is tailored for applications that require a longer cutting edge.

In addition to size and shape, we also offer a variety of surface treatments, including polishing, anodizing, powder coating, and sandblasting. These treatments not only enhance the performance of the blade but also provide additional protection against corrosion and wear.

Quality Assurance You Can Trust

When it comes to industrial components, quality is non-negotiable. That's why we have a strict quality assurance process in place to ensure that every replacement blade we produce meets the highest standards of quality and reliability.

All our blades are manufactured in accordance with ISO 2768-M tolerance standards, ensuring consistent and accurate dimensions. Additionally, every blade undergoes a comprehensive 100% inspection, covering dimensional, functional, and cosmetic aspects. This rigorous inspection process allows us to identify and rectify any potential issues before the blade leaves our facility, giving you peace of mind knowing that you're getting a product that you can trust.

Our commitment to quality is further evidenced by our ISO 9001-2015 certification. This internationally recognized standard demonstrates our dedication to maintaining a high level of quality management in all aspects of our business, from design and production to customer service and support.

Why Choose Our Custom Replacement Blades?

Industry Expertise

With over 20 years of experience in CNC machining service, we have the knowledge and expertise to deliver high-quality replacement blades that meet the most demanding requirements. Our team of skilled engineers and technicians has a deep understanding of the manufacturing process, allowing us to provide innovative solutions and technical support to our customers. Click here to learn more about our company.

Comprehensive Engineering Support

We offer more than just a product; we provide comprehensive engineering support to help you with every stage of your project. Whether you need CAD/Creo/STEP/ IGS/SOLIDWORKS support for design, DFM (Design for Manufacturing) consultation to optimize your product design, or prototype assistance to test and validate your ideas, our team is here to help.

Flexible Production Capabilities

We understand that different projects have different requirements, which is why we offer flexible production capabilities. Whether you need a small batch of replacement blades for a prototype or a large-scale order for mass production, we can accommodate your needs with a fast turnaround time. Our state-of-the-art manufacturing facilities and efficient production processes allow us to deliver high-quality products on time, every time.

Global Service and Support

Our reach extends far beyond our local borders. We have a global network of customers and partners, and we are committed to providing reliable logistics and support to clients worldwide. No matter where you are located, you can count on us to deliver your replacement blades promptly and efficiently.

Real-World Applications of Our Replacement Blades

Our custom stainless steel 316 replacement blades are used in a wide range of industries and applications. Here are just a few examples:

Marine Industry: In the marine industry, our blades are used in boat propellers, pumps, and other marine equipment. Their corrosion resistance and durability make them ideal for use in saltwater environments, ensuring reliable performance even in the harshest conditions.

Manufacturing Industry: In the manufacturing industry, our blades are used in cutting machines, presses, and other equipment. Their precision and sharpness allow for accurate and efficient cutting of various materials, improving productivity and reducing waste.

Food Processing Industry: In the food processing industry, our blades are used in slicers, dicers, and other food processing equipment. Their stainless steel construction makes them easy to clean and sanitize, ensuring compliance with strict food safety standards.

In conclusion, our custom stainless steel 316 replacement blades offer a combination of superior material quality, precision engineering, customization options, and exceptional quality assurance. With our industry expertise, comprehensive engineering support, flexible production capabilities, and global service, we are the ideal partner for all your replacement blade needs.

Whether you're looking for a standard replacement blade or a custom solution tailored to your specific requirements, we have the skills, experience, and resources to deliver a product that exceeds your expectations. Contact us today to learn more about our products and services, and let us help you find the perfect replacement blade for your application.

Marine Components Replacement: 316 Stainless Steel CNC Blade Cutter | OEM Sharp Edge for Durable Marine Equipment - Factory Direct, Custom Sizes Available & Fast Shipping

Nanjing Precision Engineering Co. Ltd.

Address

RM 1218A, Hongqiao Centre

#281 Zhongshan North Rd, Gulou District

Nanjing, Jiangsu, China

Phone: +86-138-1388-4518

Email: Cindy@njprecisionengineering.com